Thanks to HBF Contributor Aaron N for this fingers on evaluate! Aaron is a complicated brewer, very long time reader and a serial tipster!

FermZilla All Rounder

Fermenting beneath strain has been a method I’ve had my eye on for a while now and have felt the urge to experiment with it increasingly more these days. To me essentially the most interesting good thing about pressurized fermentation is that on the finish of fermentation the beer is totally carbonated and able to drink (not accounting for beers that profit from a interval of conditioning). Different advantages embrace a doubtlessly faster fermentation, a better retention of fascinating aroma compounds that in any other case may be off gassed (e.g. hop aromas), and the flexibility to ferment at hotter temperatures and not using a excessive presence of undesirable esters.

Restricted Time Deal:

MoreBeer’s Father’s Day Sale reductions FermZilla Fermenters by 20%

Test Present Pricing & Availability, Evaluation Continues Under:

I’ve been fermenting with a stainless-steel conical fermenter for the previous few years and have actually loved it. It’s straightforward to scrub, sturdy, makes pressurized transfers easy, and permits me to gather yeast for re-use. The mannequin I’ve doesn’t help pressurized fermentation as its strain restrict is 1-2 psi. Stainless-steel fermenters able to strain fermentation could be on the expensive aspect and since I don’t really have a necessity for 2 stainless conical fermenters, I couldn’t justify the fee. There’s, nonetheless, an economical method to get into pressurized fermentation due to new plastic merchandise which have entered the market within the final couple of years.

The FermZilla All Rounder is a part of Kegland’s line of plastic fermenters they’ve been growing and enhancing upon lately. Kegland is a producer out of Australia that appears to have their ear to the bottom in terms of growing merchandise that homebrewers worldwide are clamoring for. The All Rounder is particularly designed for pressurized fermentation which caught my eye and it has a gamut of extra equipment which additional drew me in. From my preliminary analysis it appeared like the right method to enter the pressurized fermentation sport and permit me to maintain my different fermentation practices like closed transfers and not using a ton of additional gear or work. Plus, coming from Kegland I knew I might belief them to place out a high quality piece of substances and I knew that they again up their merchandise with top-notch tutorial movies.

As famous, there are a number of equipment that mate with the All Rounder equipment and since I’m within the behavior of doing closed transfers, the Stainless-Metal Stress equipment appeared like a precious addition to the fermenter itself. This equipment arrived in the identical massive field as the remainder of the All Rounder bundle which included the next elements:

- 60 Liter (15.9 gallon) Fermenter

- Stainless-Metal Stand

- Stainless-Metal Deal with

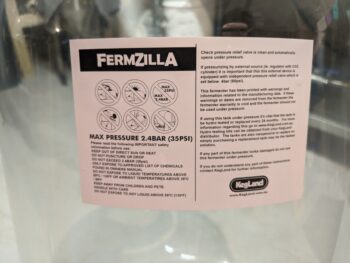

- Lid with 35 psi Stress-Launch Valve (PRV)

- 3-Piece Airlock

- Grommet Bottle Cap

- Thermometer Sticker

- Quantity Marking Sticker

- Stainless-Metal Stress equipment

- (2) Stainless-Metal Gasoline Ball Lock Posts

- Silicone tubing

- Stainless-Metal Float

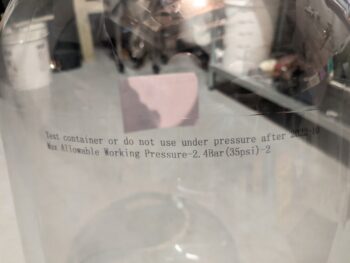

So far as high quality of fabric, all elements have been properly made and with out flaws. The grade of plastic used for the fermenter itself is akin to that of a two-liter bottle of soda. It could be a bit thicker, but when so, not by a lot. The fermenter has a date stamped on it to point its anticipated lifespan. At a sure level it’s going to should be changed, however the replacements are fairly priced. The deal with, its accompanying {hardware}, and the stand are all good high quality metal and robust sufficient to have a stable really feel to them, rigid and inflexible sufficient for his or her functions. The PRV physique is product of higher-grade plastic with a metal spring and pull ring. The airlock that got here with it’s the prevalent 3-piece selection that I’m positive each homebrewer is acquainted with. The bottle cap is a screw-on kind that, once more, is harking back to a soda bottle with the exception that there’s a grommet inset in the course of the cap’s middle to permit for the insertion of the 3-piece airlock. The thermometer sticker has each Fahrenheit and Celsius starting from 50-97 levels F in increments of 3s and 4s and from 10 to 36 levels C in increments of two. For the amount marking sticker it’s detailed to the quarter liter from 0 to 60 liters on the metric aspect and 0 to fifteen gallons on the Imperial aspect. The Stress Equipment contents had the high-grade stainless-steel gasoline ball lock posts with a feminine threaded connection, the range that may screw onto the highest of a soda bottle, in addition to 1 / 4 inch diameter barb to mate to the silicone tubing. The tubing is 31 inches lengthy and is a high quality materials. The float is so gentle it seems like it’s product of plastic, however I belief that could be a purposeful design and it’s unblemished stainless-steel.

The specs (tailored from MoreBeer’s product web page):

- 60 L (15.9 gal) Complete Quantity

- Stress Rated to 2.5 Bar (36.2 psi)

- Temperature Rated to 50°C (122°F)

- Peak in Stand – 34″

- Peak w/ Airlock – 36.5″

- Tank Diameter – 13.9″

- Lid Ports – 28 mm PCO 1881 threads

Arms on Evaluation

One of many options of Kegland’s merchandise is their documentation. Whether or not it’s in PDF or video kind, their content material is well-produced and simple to observe. The PDFs are straightforward to learn, have useful diagrams, and intention to be succinct, solely offering the mandatory information with out being too wordy – admirable! Concerning the All Rounder, their four-page documentation covers warnings, meeting, and cleansing data in addition to some useful hyperlinks all through. For his or her Unitank and All Rounder sequence of fermenters in addition they have a information to fixing leaks that has high-quality pictures and many beneficial nuggets of knowledge.

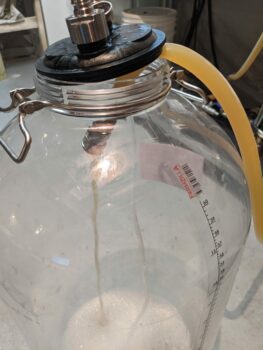

The PDFs and video got here in useful at a pair factors when assembling the All Rounder as there have been no onerous copies of the directions included with the unit. All advised, it was an intuitive meeting. The stainless steel ball lock posts screwed onto the lid simply as did the PRV. I attempted to tighten the ball lock posts down to a degree that felt cosy, however I attempted to watch out to not overtighten for concern of warping the plastic lid. This got here into play later once I realized the unit was not holding strain. That would have been prevented if I had adopted the Kegland information for fixing leaks and checked the connections previous to utilizing. As soon as the posts have been on the lid, I connected the silicone tubing to one in every of them and connected the opposite finish to the floater. I ensured the gasket was correctly seated on the lip of the lid. The amount marking and temperature sensing stickers went on the skin of the fermenter merely sufficient.

Filling the Fermenter

Come brew day, filling the fermenter was a breeze as I draped the output hose coming from my plate chiller down into the fermenter by means of the one opening on the highest. Because the empty fermenter is a bit unstable, I used to be cautious when filling to ensure the hose didn’t unbalance the rig in any respect and was additional cautious to not bump it in any respect mid-filling. The regular move of wort dropping into the fermenter completely aerated the answer as evidenced by the mass of froth on prime of the wort. After I had collected the specified quantity, I pulled the hose, pitched my yeast, positioned the lid on prime, and screwed down the lid collar as tight as I might by hand. Transferring the rig from the filling spot to my fermenter, a distance of about fifteen ft, was a precarious operation made much less difficult by the handles, however nonetheless a job being that there have been twelve gallons of liquid sloshing round inside a sixteen gallon vessel. I positioned the stand inside my fermentation chamber, propped the vessel on prime, and taped my temperature sensor to the aspect of the vessel. I’ve a thermowell on my conical fermenter and can be wanting into including one to the All Rounder sooner or later as it’s one thing that Kegland gives for the All Rounder.

Spunding Valve and Fermentation

As soon as located within the fermentation chamber, I connected a spunding valve to one of many ball lock posts on the All Rounder. Being that this was the primary time I had used a spunding valve there was a bit finding out I had achieved to piece one collectively and work out tips on how to function it. A lot credit score goes to this website for serving to me alongside the way in which. I dialed within the launch valve on the spunding valve to my desired strain, 10 psi, and left the yeast to do their work

Associated, Construct a Spunding Valve

Over the course of the subsequent few days I used to be a frequent customer to these yeasties, delighted to see them at work. It was refreshing to as soon as once more be capable of see fermentation at work, one thing I had missed whereas fermenting within the stainless conical. Though the yeast cells have been clearly energetic on every of my visits, I did discover that the strain gauge on the spunding valve was not studying a price above zero as I had anticipated. What it got here all the way down to was that there was a small leak coming from one of many ball lock posts the place it seated on the lid. I discovered this by including CO2 from my tank to the All Rounder, spraying Star-San everywhere in the lid, and seeing bubbles kind across the submit’s backside. It was at this level that I eliminated the ball lock submit and located that the gasket was not seated correctly inside it. I massaged it into place, put the submit again on the lid, discovered my Crescent wrench and tightened the submit down fairly securely. I added extra CO2 to the vessel, sprayed extra Star-San, and verified that there have been no extra leaks.

Tip: Don’t need a leak… Observe Kegland’s information for fixing leaks and checking connections previous to utilizing

On the next batch I fermented with the All Rounder I bumped into points with the fermenter holding strain as soon as once more. Inspecting all of it fastidiously I as soon as once more discovered that the gasket on of the ball lock posts was not correctly seated. I reseated the gasket and torqued on the ball lock submit, solely this time I used to be not as cautious concerning the quantity of pressure I utilized. This resulted within the threaded submit on the lid bending in close to the highest which prevents an hermetic fastening with the ball lock submit. I can be ordering a brand new lid and can be rather more cautious subsequent time to not torque down the ball lock posts too tight. I could even apply some keg lube on the gasket to encourage a greater seal with out having to tighten it as a lot.

Taking Samples

Sometimes, throughout fermentation when utilizing my conical fermenter, I’ll take samples each few days for hydrometer readings. I used to be making an attempt to determine how which may work with the All Rounder since there isn’t any pattern port like a typical conical has. I made a decision to hook up a picnic faucet to the serving ball lock submit, the one related to the floater and tubing, and draw samples. This turned out to be an environment friendly approach of drawing the liquid out, being that the vessel was beneath strain and would simply push out the beer. The one draw back is that on the strain I used to be working it beneath (~10 psi) it got here out moderately quick and I ended up with a foamy pattern in my take a look at jar. As soon as the froth subsided nonetheless, I used to be capable of get an correct studying from my hydrometer.

Chilly Crashing

After reaching my closing gravity it was time for a chilly crash. With ales I chilly crash as quickly as attainable by setting the fermentation chamber to 38 levels Fahrenheit. I used to be cautious to take away the spunding valve to keep away from suck-back in addition to monitoring the strain within the fermenter to make sure that the speedy cooling wouldn’t drop it to the purpose of collapsing the vessel partitions. As a precaution, I added a burst of CO2 a pair instances over the one to two-day technique of chilly crashing. Having set on the desired temperature for one more day and seeing that the sediment had principally all settled to the underside I knew it was time to switch.

Transferring to Kegs

Due to the lesson I realized about which submit to not use for the spunding valve it was straightforward to know which one to connect my switch line to when it got here time to maneuver the completed beer to kegs. I connected a ball lock disconnect that’s related to 2 output ball lock disconnects which I join to 2 kegs. As soon as all the pieces was connected, I opened the PRVs on the receiving kegs and watched the beer move from the fermenter by means of the strains to the kegs. By the method I added CO2 from my tank to the All Rounder three or 4 instances to make sure that the strain within the fermenter stayed above that of the kegs. My impatience might have additionally inspired me to do that extra usually than wanted with the intention to improve the move price. The switch went easily and solely took about twenty minutes earlier than I had two full kegs and an empty fermenter, other than the yeast cake and trub.

Cleanup

Following the directions from Kegland, I used scorching water to spray down the within of the vessel, eradicating nearly all of the trub and yeast cake. One of many house brewery instruments I’ve definitely gotten my good out of is Mark’s Keg and Carboy Washer. This instrument got here in useful as soon as once more in cleansing the All Rounder. I added PBW to the basin, blended it with heat water, and turned on the pump. After recirculating for fifteen minutes there was nonetheless a hoop of post-krausen residue across the prime quarter of the within of the fermenter. At this level I took a comfortable rag dipped in PBW water and was capable of take away it with a average quantity of scrubbing. The opposite items have been cleaned simply with a wipe-down and rinse. Within the case of the posts and tubing I as soon as once more made use of the Keg and Carboy Washer equipment and hooked these as much as the pump and circulated the PBW water by means of them. With all elements cleaned and rinsed I set them out to dry.

All Rounder Issues to Take into account

For beers I brew usually I like to gather and reuse yeast. This course of is made fairly easy with the conical fermenter I exploit because it permits for drawing that yeast out of the underside dump valve post-fermentation. The All Rounder doesn’t have such a function. If yeast harvesting is one thing that’s vital to the brewer, it’d show harder with the All Rounder. I consider it may be achieved by fastidiously accumulating it after transferring the totally fermented beer off by pouring it right into a sanitized vessel, it might simply be trickier than with a conical.

When practically crammed, the 15.9 gallon All Rounder was cumbersome to maneuver. It was heavy and awkward to maneuver throughout a room. I’d not advocate transferring it up or down stairs with out assist. The transferring strap would definitely make transport simpler and fewer harmful. When empty, the fermenter can be a bit awkward as it’s top-heavy and susceptible to falling over even when securely on the stand.

The fabric comparability to stainless already made, the opposite observe on the fabric is that the fermenter physique plastic isn’t the best grade of fabric. I consider it’s completely passable for the aim it serves, and it’s what makes it an reasonably priced piece of substances. Moreover, as famous concerning the lid changing into deformed because of my enthusiasm for overtightening, I consider it might be an improve to have a stainless-steel lid, however that would definitely bump the price of the unit up.

All Rounder Advantages

Already famous, however value mentioning once more is the cost-effectiveness of the All Rounder. For beneath $100 one can have a high-quality fermenter that’s able to strain fermentation with none additional modification. In comparison with a stainless fermenter that does the identical factor, one can purchase an All Rounder for a fraction of the price of the stainless gear.

Though I’ve not tried it, the All Rounder is a serving-capable vessel. I can see how it might be straightforward to do and can be a method to scale back the quantity of substances a homebrewer maintains (however who amongst us are really destined to have much less gear?). To have a vessel to ferment, carbonate, and serve 5 or ten plus gallons at a time can be interesting to these with out a variety of area or are looking for simplicity.

The cleansing facet of the All Rounder is engaging. In comparison with stainless it will not be as sturdy simply by the character of the fabric, however it was easy to scrub and simple to see when all residue was eliminated. If cared for correctly, it ought to final a number of years if not longer.

Kegland continues to innovate new merchandise and equipment that mate with this sequence of fermenter. At present out there are the strain equipment which I’ve outlined, a thermowell to allow a extra exact measure of fermentation temperature, a transferring strap that makes transporting the vessel simpler and safer, in addition to a floating dip tube filter that helps to dam hop particulate and different solids from getting sucked up by the switch tube. The help that exists and the prospect for continued innovation on this product line are definitely encouraging. The truth is, Kegland has a nifty dry hop equipment on their website, however it’s at present not supplied outdoors of Australia. I put in a request to MoreBeer so hopefully that can be on its method to the US of A in time.

Conclusions

Whether or not seeking to get into strain fermentation or simply searching for a brand new fermenter, the All Rounder deserves consideration. It’s properly made by an organization that backs up their merchandise with help and high quality documentation and is dedicated to persevering with to make the product line maximally helpful to house brewers. I look ahead to mastering the artwork of strain fermentation and believe that the All Rounder will serve me properly all through this endeavor.

Test Present Pricing & Availability:

Intently Associated or Talked about on this Evaluation:

Extra Pictures

Extra Kegland Gear Opinions!

Extra Fermenter Opinions!

Extra Homebrew Finds!

Extra Fermentation Associated!

Particular thanks for MoreBeer for offering the unit used for analysis on this evaluate.

Value, promotions and availability can change rapidly. Test the product web page for present worth, description and availability.

Be certain that the elements you utilize are suitable and rated on your meant software. Contact producer with questions on suitability or a selected software. At all times learn and observe producer instructions. evaluate:allrounder tag:tpr