Restricted Time Deal, Assessment Continues Under:

Monster Mill Sale: Monster Brewing {Hardware} is discounting choose 2 on 3 curler mills

I reported this sale some time again. As of this posting, costs have dropped much more. The two curler professional mill is $219, save $90, the three curler full package is simply $199 and the three curler professional mill is $319, save $120.

Monster Mill MM-3

I began milling my very own grains not too lengthy after I switched to all-grain. At first I believed the thought was laughable to mill my very own grains- why purchase one thing and do the work myself, once I may get it completed free of charge on the homebrew store? However as soon as my course of had stabilized a good quantity, I turned annoyed by my lack of ability to hit the recipe’s deliberate OG. On my batches the place my gravity was decrease than predicted, I discovered a notable variety of totally intact grains within the spent grains from my mash. Aiming for consistency, I wished to verify all my grains had been at all times crushed, so I purchased a 2-roller grain mill. That labored properly, but when I wished to optimize mash effectivity, I used to be at all times dancing on the sting of a caught mash.

The three-roller mill from Monster Brewing {Hardware} passes by means of a primary pair of rollers which have a set hole. That’s machined to be 0.060”, with the intention of doing a minimal crush to melt the within of the grain with out actually breaking the husk. After the primary pair of rollers, it passes by means of the hole that you may alter to your liking. The directions supplied with the mill suggest 0.045” for a medium crush, 0.055” for a rough crush, and 0.038” for a advantageous crush. However in fact the great thing about having your individual mill is you may alter it as you need, primarily based on what works greatest for you.

The MM-3 3-roller mill comes with some choices. The bottom rollers are 1144 metal alloy that’s sturdy for lengthy life, however can get some floor rust if utilized in a non-climate-controlled space, or in case you moist mill your grain. For these homebrewers, they provide a stainless-steel curler possibility, which they are saying has the identical sturdiness because the metal alloy base rollers. If you’re a manic homebrewer, they provide a third possibility with their MM-3 Professional collection, which has warmth handled rollers. These apparently have about 10x the life sturdiness, however the price ticket roughly doubles over the bottom MM-3.

The opposite possibility to select from is the drive shaft measurement. Customary is a 1/2″ drive, however 3/8” is on the market as a smaller possibility. The three/8” actually isn’t really useful since 3/8” drive drills sometimes don’t have the torque to drive this mill. It can be laborious to discover a cordless drill with sufficient torque to drive it, so Monster Mill recommends a corded drill. For those who order the grain hopper from Monster Mill, it comes normal in galvanized 20-gauge metal, or optionally available chrome steel. Galvanized metal is corrosion resistant, so the one actual benefit of stainless on your grain hopper is the “bling impact”.

Examine Costs & Monster Mill Choices, Assessment Continues Under

When purchasing for a mill, it’s essential to acknowledge that even when a product seems the identical/related in an image, there’s extra to it than the picture. For instance, there’s a related 3-roller mill out there at a cheaper price. Nonetheless, what you may’t inform from the image is that the rollers are manufactured from a less expensive metal that doesn’t put on as properly, and makes use of non-sealed bearings that are liable to grain mud inflicting put on issues. Fred Francis, the proprietor of Monster Mill makes some extent of sourcing all of his uncooked supplies from the U.S., and assembling the mills in Georgia. Quite than chase the bottom value level out there right down to the underside, he focuses on his American provide base and protecting top quality design/supplies to make sure a sturdy product that stands up properly with word-of-mouth suggestions

Fingers on Trial

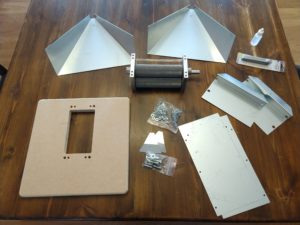

The very first thing I seen was how meticulously the packaging was designed. Seeing the straightforward flat field on my doorstep, I virtually contacted Monster Mill to inform them they forgot to ship my grain hopper and base. Fortunately I opened the field first, to keep away from my embarrassment. Elements had been nested in particular spots, properly supported for cover in transport and making essentially the most use of the area accessible. The smaller field measurement makes transport cheaper, but it surely additionally means you don’t should take care of transport one thing again as a result of it arrived bent or scratched. I evaluate a whole lot of gear, and the care taken in designing packaging is normally a superb indicator of the standard of the design of the product.

Whereas unpacking the mill, I seen the rollers had a whole lot of residual machining oil on them. I sometimes learn directions, however on this event, I dug in and gave them a superb cleansing to eliminate the oil. After I noticed the rust forming inside a seemingly wonderful quick period of time, I learn the manual- “Earlier than utilizing your mill the primary time, run a pound or so of malt by means of it just a few instances to wash the rollers. After milling, brush the grain mud off the rollers with a dry brush or use compressed air. Don’t use water.” Fortunately, with use of a nylon bristle brush, and the suggestion of working grain by means of it, the rust was now not seen. Study from my mistake.

The hopper was easy to assemble with the little machine screws, washers, and nylon-insert lock nuts. And one other good be aware of consideration to element, the galvanized metal hopper partitions had no sharp edges. A mix of the sturdy gauge, and good machining practices left me with unscathed arms on the finish of meeting.

Adjustment of the curler hole was tough. With the mill mounted to the bottom, I couldn’t get a straight shot in between the adjustable curler and the drive curler. I made use of feeler gauges that had a 45-degree angle bent into them and this labored pretty properly. To be actually correct, I’d’ve wanted to unbolt the mill from the bottom, however that appeared like an excessive amount of work. I additionally examined out their suggestion on drills. I attempted my cordless drill [DeWalt Model DCD771 20V] and wasn’t in a position to make it even transfer, so I went with my corded drill [DeWalt Model DW236] to energy by means of it.

For this analysis, I arrange a small mash experiment. I had beforehand run a mash conversion effectivity trial on my 2-roller mill, to find out the hole to make use of with that mill. There are in fact one million variables contributing to mash effectivity. I attempted to attenuate these results by mashing with grain from the identical batch, similar water adjustment salts/acid, similar mash profile, and similar mash tun. From that experiment, it confirmed a 7% enchancment in mash effectivity with grain milled at 0.026” versus 0.034”. In order that’s been my normal set-up since then. The draw back from this was semi-frequent caught mashes and the necessity to complement my grain invoice with rice hulls to attempt to counteract this impact.

For the Monster Mill MM-3, I used grain from a single 55-lb bag of malt (Viking Xtra Pale malt from MoreBeer). Mashed it in a Chapman Thermobarrel – Fingers on Assessment – whereas working recirculation by means of my Blichmann RIMS Rocket – Fingers on Assessment. All of those trials used 9 lbs. of the malt, mixed with brewing salts and acid to succeed in a mash pH measured of 5.3. I mashed for an hour at 149F, then raised temperature to 168F for a ten minute mash out. I collected all the primary runnings in my kettle, then added all the sparge water to the mash tun, stirred issues up, recirculated for 10 minutes, then drained all of that into the boil kettle as properly.

Trial 1 Baseline

The primary batch I did was to ascertain my baseline with this new mash tun and new grain, utilizing my 2-roller mill set to 0.026” hole. With this configuration, I achieved a mash effectivity of 80%. And unsurprisingly, I acquired a caught mash at one level whereas recirculating which I needed to break away from the false backside and decelerate the recirculation pump movement price.

Trial 2

For the second batch, I used the MM-3 set to 0.035” hole. Qualitatively, I may see when evaluating the crushed grains, that the MM-3 had significantly better grain husk construction to assist filtering within the mash mattress. The two-roller with the finer crush had a whole lot of grains pulverized to a flour-like consistency. With the MM-3 at 0.035” hole, I achieved a mash effectivity of 78%. With solely a 2% distinction to the primary run with the 2-roller mill, this might very properly have simply been measurement variation.

Trial 3

For the third batch, I adjusted the MM-3 down barely to a 0.033” hole. I additionally ran some grain by means of my 2-roller mill with this similar 0.033” hole to do a qualitative/visible comparability. The two-roller mill had a small quantity of complete kernels that hadn’t been cracked at this hole setting, whereas the 3-roller MM-3 had cracked each kernel. Some had been extra intact than others, however all had been cracked, with the endosperm uncovered to soaking in mash water to extract its sugars. This 0.033” hole on the MM-3 resulted in an 80% mash effectivity.

Conclusions

In conclusion, the MM-3 was in a position to obtain the identical mash effectivity as my 2-roller mill, however accomplish that at a niche setting that didn’t depart me liable to caught mashes. And whereas brewing electrical with a RIMS system, you prefer to make the most of the management and go about doing different issues throughout mashing with out having to babysit to keep away from scorched wort or dry working your pump. In order that’s a major end result for my electrical brewing setup. The standard of the mill is nice, and appears heavy obligation. Undoubtedly looks like it has a protracted life forward of it.

Get the Gear

Talked about in This Assessment:

Get a Deal on Bulk Grain

A Deal on All Grain Kits

Adventures in Homebrewing and Austin Homebrew Provide usually low cost seasonal homebrew beer recipe kits by 20%. Choices embrace each all grain and extract choices.

Grain Storage Choices!

Milling Your Personal Grain

For all grain brewers, bulk grain storage goes hand in hand with milling your individual grain. If we’re storing bulk portions of grain to save lots of money and time, we’re in all probability going to want to mill that grain.

Milling your individual grain gives these benefits…

- Offers you management over the crush of your grain. That’s an enormous think about effectivity. A mill permits you to advantageous tune on your tools and course of.

- A mill permits you to get monetary savings by shopping for complete baggage of grain.

- Freshly milled grain = higher tasting beer.

Extra Pictures

Extra Mill Critiques!

Every thing All Grain!

Our useful resource publish on all grain is the supply for every little thing all grain!

Extra Homebrew Finds!

Particular Because of Monster Brewing {Hardware} for offering the unit used for analysis on this evaluate.

By Brad Probert. Try Brad’s web site – beersnobby.com

Make sure that the elements you utilize are appropriate and rated on your supposed utility. Contact producer with questions on suitability or a particular utility. At all times learn and observe producer instructions. evaluate:mm tag:tpr rs:5