Thanks to HBF Contributor Aaron Nord for this arms on overview! Aaron is a complicated award successful brewer, a very long time reader and a serial tipster!

Kegland Hop Bong

Preserving oxygen out of a fermenter after the preliminary yeast pitch is a aim of most fermentations, with a number of exceptions being oxygenating a excessive gravity batch mid-way by fermentation, barrel-aged ales, or spontaneously fermented ales in open foeders. For a homebrewer who needs to brew a beer exterior of these exceptions famous, avoiding oxygen introduction after fermentation has begun is paramount to a top quality completed beer, a aim which is usually a troublesome to achieve. Notably, including dry hops, different taste parts (e.g. wooden chips or espresso beans), or clarifying brokers (e.g. gelatin fining or Biofine) presents a problem for many homebrewers in the event that they wish to keep away from oxygen publicity within the fermenting wort.

There are workarounds and methods for homebrewers to restrict oxygen introduction, conceived upon by artful brewers through the years. Dry hops for instance, could be suspended in a muslin bag above the wort by inserting a magnet contained in the bag and its mating magnet on the skin of the fermenter. On this approach, the hops will likely be within the fermenter in the beginning of fermentation and could be dropped in keeping with the dry hop schedule by merely eradicating the skin magnet, all with out opening the fermenter. Or, so as to add clarifying brokers with out cracking the fermenter lid, a brewer can make the most of a plastic bottle with a carbonation cap. This technique entails including the liquid substance to a plastic soda bottle and pressurizing the bottle with CO2 by way of the carbonation cap, purging it, and repeating the method a number of instances to make sure the gasoline contained in the bottle is usually composed of CO2. Then, through the use of a ball lock jumper, the pressurized bottle could be related to a fermenter’s ball lock put up, if geared up, and the liquid will enter the fermenter, as long as the strain within the fermenter is lower than that of the bottle.

Though these workarounds exist and minimize the mustard for my functions, I used to be excited once I came upon that Kegland was set to launch a product that seemed to be an easier answer throughout. In trying into it additional I discovered that it was marketed to have further makes use of, except for the primary characteristic of enabling hop, taste, or fining additions to the fermenter whereas limiting oxygen ingress. This extremely anticipated product is named the Hop Bong.

I’ve been a proud proprietor of a Kegland FermZilla All Rounder fermenter – Fingers on Evaluate – for over two years now and don’t have anything however good issues to say about it. As a producer, Kegland is a homebrewing gear innovator and a pacesetter available in the market. They’re persevering with to provide you with novel gear and instruments that span their big selection of product choices together with many for his or her FermZilla fermenter line. I used to be excited to see what the Hop Bong may provide as an addition to my All Rounder fermenter.

Kegland Hop Bong Present Worth & Availability:

by way of MoreBeer

by way of William’s Brewing

Associated: FermZilla Critiques!

The Hop Bong package has a number of parts relying on which package deal a brewer chooses. MoreBeer has two kits which characteristic a 2 inch Hop Bong: one for current FermZilla patrons and one that features every thing vital for strain fermentation, fitted to these new to FermZilla. Kegland additionally provides a 1.5 inch Hop Bong, but it surely might not be accessible within the US as of this writing. The fundamental package from MoreBeer consists of the primary chamber, referred to as the Hop Bong, with 2 inch tri-clamp (T.C.) ends and an angled port threaded to obtain a ball lock put up, a cap that mates to the two inch T.C. high of the Hop Bong that has a pull-ring pressure-release valve (PRV) on the topmost half, a 2 inch tri-conical butterfly valve, and T.C. strain lid. The strain lid has a 2 inch T.C. high, an hooked up PRV much like one on a corny keg, two threaded ports to connect ball lock posts, and a backside that’s the identical measurement because the FermZilla fermenter lids.

Contents as listed by MoreBeer:

- FermZilla 2″ T.C. Strain Lid Starter Equipment

- 2″ Hop Bong

- 2″ FermZilla Tri-Conical Butterfly Valve

- Crimson PRV & PCO1881 Cap Combo

- Yellow Ball Lock Cap

- (2) Crimson Ball Lock Caps

- (2) 2″ Tri-Clamps

- (2) 2″ Silicone T.C. Gaskets

The improve package comes with a floating dip tube with filter attachment.

The Hop Bong itself is product of a high-grade polymer which may tolerate excessive temperatures. Additionally it is able to withstanding sanitization in an autoclave. It’s fully clear, permitting the monitoring of the contents fairly simply. The dimensions of the chamber is such that it may well maintain about six ounces or 180 grams of hops.

Kegland Hop Bong Elements, Construct High quality and Meeting

The butterfly valve is like these discovered on different FermZilla fermenters like their Tri-Conical. It has a stable motion for opening and shutting and makes an air-tight seal when closed.

The tri-clamps are hefty and on the higher finish of the standard scale in comparison with different tri-clamps I’ve dealt with. They’re product of stainless-steel. The silicone seals for the tri-clamp are additionally excessive grade.

General, the standard of the supplies is what I’ve come to count on from a Kegland product. It’s properly engineered and designed with the homebrewer in thoughts.

Additionally Options Kegland Carb Caps…

Assembling the Hop Bong was easy, and all items match collectively as anticipated. Kegland has educational movies on the Hop Bong which element meeting and utilization and, like their different movies, are clear, concise, and useful.

Makes use of for The Hop Bong

Though the primary objective of the Hop Bong is to ship hops or varied different mid/post-fermentation additions to a fermenting wort or completed beer, it may well serve in different capacities as properly. Outfitted with a carbonation stone, it may well function both an in-line oxygenator or carbonator for wort/beer travelling by the chamber. This may be achieved by attaching the carbonation stone to the underside of a carbonation cap which is then hooked up to the angled port on the Hop Bong’s foremost chamber. Then both finish of the chamber is fitted with a cap and the cap is fitted with carbonation caps.

One other potential use is as a hop randall. Outfitted as described for oxygenation/carbonation minus the carbonation stone, the primary chamber could be stuffed with hops (or different desired taste parts) and a completed beer could be pushed by the chamber, selecting up flavors on its approach by.

Fingers on Evaluate

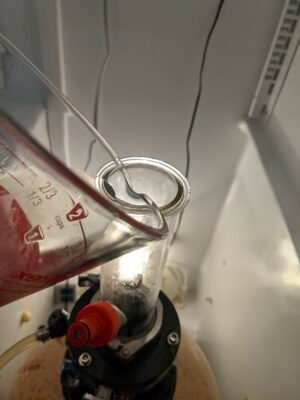

The primary likelihood I had to make use of my Hop Bong was on an Additional Particular Bitter. Since I don’t usually add dry hops or every other taste additions to this brew, I needed to wait till the tip of fermentation and subsequent chilly crash for the gelatin fining addition. I began by making ready the answer and sanitizing the Hop Bong chamber and hooked up elements. Then, already having the cap off so I may sanitize the meeting, I merely poured the gelatin answer into the chamber. I changed the lid, checked to ensure the silicone seal was in place, then tightened the tri-clamp. At this level I set my CO2 tank to fifteen psi and hooked up the CO2 line to the carbonation cap on the Hop Bong. This crammed the chamber with CO2 which I flushed by pulling on the PRV on the highest cap of the Hop Bong. I repeated this course of ten instances to make sure that a lot of the oxygen had been changed with CO2 within the chamber. I charged the chamber as soon as extra earlier than turning the deal with on the butterfly valve ninety levels, dropping the gelatin answer into the All Rounder vessel. After I may see that every one the answer had dropped, I moved the deal with of the butterfly valve again into the closed place. Inside thirty seconds, I had launched almost oxygen free gelatin finings into my fermented ESB, one thing I had solely performed beforehand with a workaround that was not superb.

After this one easy use case I used to be already assured that I used to be going to get pleasure from utilizing the Hop Bong going ahead to carry out different additions to my fermentations, all with the safety of figuring out I used to be retaining oxygen ingress to a minimal.

This primary foray with the Hop Bong was pleasing for different causes. It was a easy sufficient course of that didn’t contain a bunch of cobbled collectively items – all of it simply labored from the field. The actions have been all satisfying from pulling the PRV to the opening and shutting motion of the butterfly valve. Cleanup was easy, because the Hop Bong itself is product of such laborious, high-quality polymer it was straightforward sufficient to wash with a material and brush in a shower of sizzling water and oxygen-based cleanser. The opposite elements have been equally cleaned, no completely different than many different widespread items of brewing gear.

I used to be trying ahead to my subsequent likelihood to make use of the Hop Bong and wished to check its foremost marketed use. There’s a model of beer which generally contains dry hops I had not brewed earlier than however wished to attempt my hand at – an Italian pilsner. I put the recipe collectively and penciled the brew date in my calendar, being certain to incorporate the dates of the 2 dry hop additions. Brew day went properly and on the finish I had eleven gallons of pilsner wort in my All Rounder fermenter being labored on by some completely happy lager yeast. At day six it was time so as to add the primary dry hop addition, a small dose of solely seven grams of Hallertauer Mittelfrueh. The method was like that of the gelatin fining addition talked about beforehand the place the cost was added to the Hop Bong chamber which was purged with CO2 ten instances after which launched into the primary fermenter with the flip of the butterfly valve. The one distinction was that this time I pushed extra CO2 into the Hop Bong whereas the butterfly valve was open, encouraging any hop remnants that caught to the Hop Bong partitions (miniscule if any) down into the fermenter, being certain to not overcharge the primary fermenter chamber with CO2. This course of was repeated as soon as once more on day 13 when 21 grams of Saphir hops have been added in the identical style and as soon as once more on the finish of fermentation and chilly crash for the gelatin finings.

The following makes use of of the Hop Bong have been simply as satisfying as the primary one. The Chilly IPA I most just lately brewed referred to as for a few dry hop additions and one with 240 grams of hops. This addition was break up into two cycles by the Hop Bong because it was only a bit an excessive amount of for one fill of the chamber.

Having used the Hop Bong now a number of instances I can say that it actually fulfilled the precise objective it was designed to realize. It did this all whereas giving me a sense of accomplishment in having dosed an actively fermenting wort with oxygen-purged components in a way not dissimilar to {that a} skilled brewer may make use of. With the ability to maintain that low-oxygen atmosphere whereas including these components in keeping with the recipe will get me one step nearer to having fun with the idealized completed beer, one the place there’s a decrease potential of off-flavors launched by oxygen, a decrease likelihood of staling shortly, and one which had these additions launched on schedule with out using some cobbled collectively home made equipment with a excessive potential for leaks or failure.

The one critiques I’ve of the Hop Bong must do with the way it match with the fermenter itself. As acknowledged beforehand, placing all of it collectively was easy and each piece match collectively properly, but it surely was a bit awkward as soon as the meeting was on high of the fermenter. Having the meeting on high of the fermenter made it a bit tricker to entry the carbonation caps and thermowell on the fermenter lid, so tough the truth is that I didn’t get my spunding valve secured all the best way on the carbonation cap the primary time. This resulted in a spike in strain earlier than I used to be in a position to appropriate it. It was additionally harder to tighten the carbonation cap on the fermenter lid whereas the Hop Bong was hooked up as I needed to maneuver my wrench across the Hop Bong. One different little bit of awkwardness offered itself when turning the deal with on the butterfly valve. The motion of the valve itself was certainly stable. Nevertheless, as a result of torque I wanted to use to it for it to maneuver freely, it tilted the Hop Bong meeting to the purpose I heard strain escaping from the T.C. valve connection level between the underside of the Hop Bong and the highest of the fermenter lid. This might probably have been remedied by tightening the T.C. clamp at that union, however I can see this as being a potential level of failure sooner or later and can monitor it going ahead. Lastly, I might suggest placing the tightening ring on over the fermenter lid earlier than placing the carbonation caps on, in any other case the caps will likely be an excessive amount of of an obstruction.

Abstract

The Hop Bong is a powerful addition to the FermZilla line of fermenters and one which makes me excited to look to the longer term to see what Kegland has coming down the pike. As common with Kegland merchandise, the parts are properly designed and created from top quality supplies so it ought to final a very long time. It offers me larger confidence in all my beers, however particularly ones with a number of mid-fermentation additions, that they are going to be freer of flaws and age properly over time. The Hop Bong is a must have addition to any of the FermZilla fermenters and properly definitely worth the funding.

Kegland Hop Bong Present Worth & Availability:

by way of MoreBeer

by way of William’s Brewing

FermZilla Critiques!

Extra Pictures

Latest Hop Offers!

Fermenter Critiques

Extra Kegland Gear Critiques!

Extra Homebrew Finds!

Worth, promotions and availability can change shortly. Examine the product web page for present worth, description and availability.

Make sure that the parts you utilize are appropriate and rated in your supposed software. Contact producer with questions on suitability or a selected software. At all times learn and comply with producer instructions

Thanks to MoreBeer for offering the models used for analysis on this overview.

Worth, promotions and availability can change shortly. Examine the product web page for present worth, description and availability. overview:klhb tag:tpr