Again in 2014, I had what I might name a fairly properly put collectively and balanced kegerator. Despite that, for years, I had handled the dreaded first foamy pint of beer. After that pint of beer, beer would pour nice. That’s till a major delay between pours – in a single day or a number of hours.

Associated Assets – Foam Management & Kegerator Balancing

Diagnose Different Points

A Nearer Have a look at Kegerator Beer Line Temps

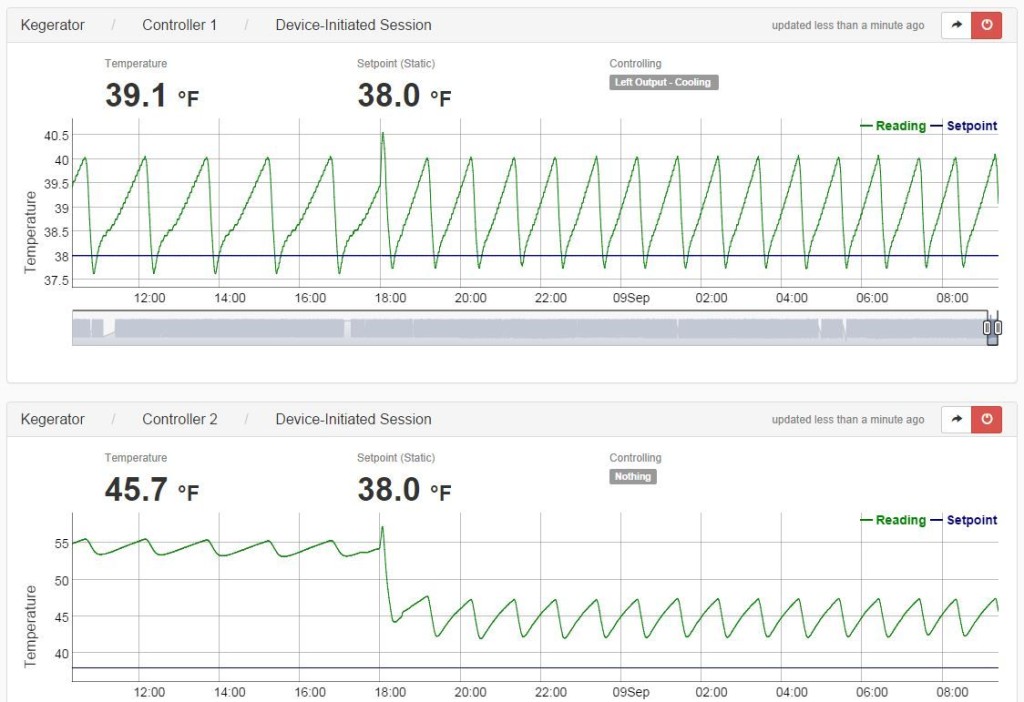

Beer Line Temps – No Recirculation Fan

The reason for the issue is fairly clear. Warmth rises. Meaning the highest of your kegerator goes to be hotter than the underside of your kegerator. That hotter beer foams when it comes out. The tap and shank are additionally hotter. That heat provides to the issue.

How a lot is the temperature variance? After all, this can fluctuate from setup to setup and local weather to local weather. I used to be comparatively shocked by the temperature distinction in my very own kegerator.

The highest studying about mid keg and the underside studying is the highest the highest of my beer traces. These are about 22″ aside. This graph exhibits a cut-off date variance between the 2 of 14.9 levels F. My beer is concerning the temperature I need it, however the prime of my serving line is far hotter. That distinction in temperature causes the primary pint to have an excessive amount of foam. Pours that occur quickly after the primary are positive. The tubing, shank and beer are comparatively cool.

Including a Recirculating Fan to Scale back Beer Foam

Outcomes!

This graph illustrates the results of including the recirculation fan within my kegerator. Previous to the fan, the tubing temperature spiked to round 55.4 deg F. After the deep freeze kicked on, the tubing dropped to round 53.15 deg F. Not a giant change. That averages out to 54.275 deg F.

You may see the purpose on this graph the place the fan is turned on. The temperature drops sharply. The brand new is excessive 47.3 deg F and the brand new low is 42.13 deg F for a median of 44.715 deg F.

- Earlier than – Avg Tubing Temp = 54.275, Avg Mid Keg Temp = 38.83, Dif = 15.445 deg F

- After – Avg Tubing Temp = 44.715, Avg Mid Keg Temp = 38.89, Dif = 5.825 deg F

The recirculation fan dropped my tubing temperature by 9.62 deg F (62%). Virtually talking, that distinction is sufficient to make each pint pour proper. My first pint pours appropriately… I like that!

Associated: Rebuild Your Kegs!

I bought this fan in April of 2014 and began utilizing it quickly after. As of this replace in August of 2020 the identical fan continues to work nice. It has been working repeatedly in my kegerator years. Word – I do use an Eva-dry E-500 in my kegerator to assist deal with kegerator condensation. See: Dealing with Kegerator Condensation with the Eva Dry E-500. I theorize that retaining condensation underneath management might play a giant half in fan longevity.

What are others saying? Search this product’s Amazon evaluations for “kegerator” and “keezer” – might embrace evaluations for different sizes or variations

AC Infinity AXIAL 8038, Quiet Muffin Fan, 115V 120V AC 80mm x 38mm Low Pace, for DIY Cooling Air flow Exhaust Initiatives – observe that a number of variations of this product could also be accessible, as such a distinct model might seem at this hyperlink

Associated: Three Prime Ideas for Keezer Conversions!

Diagnose Different Foam Associated Points

Extra Homebrew Finds!

Associated Assets – Foam Management & Kegerator Balancing

Latest Offers!

10 Most Latest Homebrew Useful resource Posts & How-To’s!

We’re Homebrew Assessment HQ! Our 10 Most Latest Critiques

Additionally: Kegerator Ideas & Gear | Keg Restore Half #s | Latest Keg Finds

Our Prime Draft Assets!

It is a Prime Publish! See: All Prime Posts

Make certain the elements you employ are suitable and rated in your meant utility. Contact producer with questions on suitability or a particular utility. At all times learn and observe producer instructions. toppost:recircfan tag:tpr rs:6