Go forward, name us romantic. However increasingly today, we’re curious about uncovering and exploring everybody that’s had a hand in making the beer we’re ingesting. So typically we focus solely on the liquid within the can that we overlook all of the disparate parts that got here collectively to make that beer. From the hop growers and maltsters offering important hops and malts all the best way to the tools suppliers supplying the very machines that guarantee breweries may even perform each day.

With over 9,000 breweries now working in america, it stands to purpose {that a} brewery wants top-of-the-line tools as a way to succeed. Particularly main breweries experiencing durations of development similar to Brooklyn Brewery, Yards Brewing, and Faubourg Brewing Co. (previously Dixie Brewing), maintaining their high quality constant and their manufacturing environment friendly requires precision instruments.

And as a rule, after we speak to breweries about what tools they’re utilizing, one specific title retains showing.

Because the early twentieth century, Alfa Laval has led the best way in offering first-rate tools for the brewing business from centrifuges to flash pasteurizers and all the pieces in between.

So it’s no shock to see among the most-noteworthy breweries within the nation turning to Alfa Laval after they began to develop.

Brooklyn Brewery: Enhance Capability, Effectivity, and Yield

Through the mid-2010s Brooklyn Brewery skilled a interval of pretty massive manufacturing development, pushed partly by their shipments to nations abroad.

For one of the crucial iconic breweries not solely in New York Metropolis, but in addition the complete nation, when it got here time to scale up their tools, they seemed for the best companion to assist them.

“We have been going by a interval of manufacturing development, attempting to extend our capability and on the lookout for methods to enhance our course of effectivity and our yields…that coincided with doing a variety of delivery to different nations the place requirements and tolerances in ABV specs have been in some instances extra strict than america,” says Brooklyn Brewery Director of Brewery Tasks and Improvement Kyle Wilson. “It was actually important we hit these targets…so we seemed to Alfa Laval.”

Wilson had beforehand labored with Alfa Laval tools whereas brewing at one other main Craft operation, in CA.

Extensively revered and recognized all through the business, Alfa Laval rose to the highest after Wilson mentioned they checked out a handful of different brewery tools corporations. “We knew they have been legit as a result of so many individuals use them and so they have a protracted, lengthy record of buyer references we talked to as effectively.”

In nearly three to 4 years, Brooklyn Brewery invested in 4 or 5 essential items of apparatus just like the Alfa Laval ALDOX totally computerized water deaeration system, the CARBOBLEND, and even a number of bespoke tasks.

Maybe crucial although: the Alfa Laval CARBOBLEND. The mixing and carbonation system helped Brooklyn Brewery hit carbonation and ABV specs for a given recipe mechanically and with pinpoint accuracy.

“We have been popping out of a course of the place we had relied on finest follow and operator intervention to realize these outcomes, which is clearly not 100% efficient,” says Wilson. “Concurrently reaching these actually necessary high quality and consistency metrics that beforehand had been exhausting for us to hit with consistency was an enormous factor.”

Greater than that, hitting these specs was truly a requirement. “We might not have been in a position to obtain the outcomes that we wanted to for compliance causes in these different nations with out that piece of apparatus,” says Wilson.

For different wants, Brooklyn Brewery required a extra personalised method, creating three custom-made warmth exchangers with Alfa Laval.

One for his or her bottle-refermented merchandise, one other to chill beer after operating by the centrifuge, and a remaining much more esoteric one for Brooklyn Brewery’s bitter beers.

“These beers required, as part of an early [step] within the recipe and the manufacturing, a bacterial fermentation with lactic acid micro organism that wanted to occur at very managed larger temperatures,” says Wilson. “That’s one other piece of apparatus, we designed with Alfa Laval’s assist, that we nonetheless use on a regular basis and works very well.”

It’s this further degree of white-glove service that Wilson says carried over proper from day one.

“Their crew has all the time been prepared to downside remedy with us or give you customized options to distinctive issues,” says Wilson. “The craft beer business is so full of individuals attempting to do bizarre issues that off-the-shelf tools doesn’t essentially serve, so Alfa Laval has been an amazing companion in serving to us cope with extra unconventional merchandise and processes.”

In actual fact, Wilson says that they’ve been so pleased with their expertise with Alfa Laval that shifting ahead, “if we’re ever shopping for a centrifuge or one thing Alfa Laval provides, we’re not even on the lookout for different bids, we’re simply going straight to Alfa Laval.”

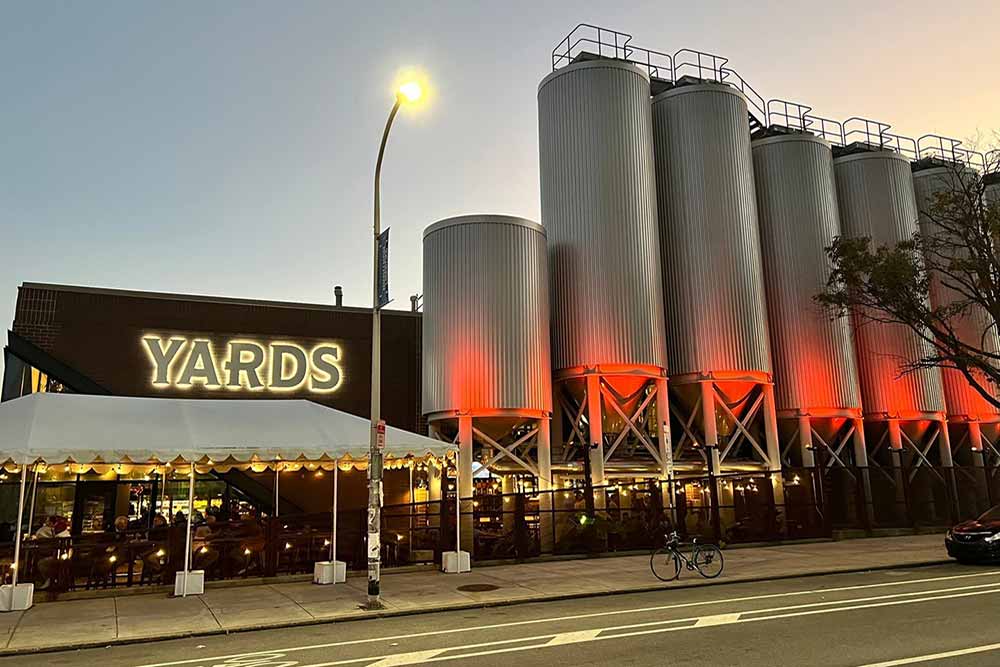

A sentiment Yards Brewing Founder, President, and Brewmaster Tom Kehoe shared after working with Alfa Laval to outfit their total new 80,000-sq-ft facility on Spring Backyard Avenue in Philadelphia

Yards Brewing: Going Full Velocity Forward Absolutely Automated

In 2017, Yards Brewing made an enormous transfer. Since 1994, Kehoe had been operating the enduring brewery out of a 42,000-sq-ft principally guide brewhouse on Delaware Avenue in Philadelphia.

However fairly merely, “We simply wanted a brand new area,” says Kehoe.

Trying to transfer extra beer into cans, Kehoe went all out for the brand new Spring Backyard Avenue location, switching to a totally automated brewery.

“We needed to make a press release and we needed to get one of the best that we might,” says Kehoe.

To make sure they reached their capability and high quality objectives, Yards recognized the Chilly Block as a significant space of want. Particularly, a yeast plant, CIP plant, filtration tools, and interconnecting piping or routing have been designated as “necessities.”

So the brewery did their due diligence, researching three totally different tools suppliers. In the long run, Yards invested in all Alfa Laval tools for his or her Chilly Block together with an ALDOX deaeration system, a CARBOBLEND, and a Flexitherm and outfitting the yeast room, which Kehoe calls “the showpiece.”

Yeast has a particular which means at Yards. Utilizing a pressure that’s pretty thick, Yards knew they wanted some equipment geared up to deal with their distinctive constraints. The Alfa Laval SCANDI BREW yeast propagation tools match the invoice.

Moreover, Kehoe factors out the valve matrix, calling it the “site visitors cop that sends beer all by the brewery in the best path.” He says, “It’s actually neat to have one in every of them and see it working; that was lovely and one of many greater issues we knew we wanted.”

From a technological perspective, it’s seemingly small adjustments like an automatic valve matrix which have made a world of distinction. “We knew we have been going to develop however we didn’t suppose we’d want the know-how as quickly as we did,” says Kehoe. “Alfa Laval would counsel one thing and we’d take a step again and say why are you suggesting that, and it could grow to be actually clear that they knew just a little bit extra about how we’d develop then even we did!”

It’s that degree of experience and meticulous care that basically sealed the deal for Yards. Taking the time to handle Yards’ particular challenges with out being overbearing made an enormous impression on Kehoe.

“It’s good to work with an organization that may actually maintain your wants and you understand all the pieces will combine effectively collectively,” says Kehoe. “We belief these guys to provide us with one thing we all know we’ll want and so they’re not going to promote us one thing we don’t.”

For instance, Kehoe says that, similar to Wilson, they’re seeking to seize a centrifuge sooner or later. And it ought to come as no shock that they’re turning to Alfa Laval to provide them with the recommendation and tools they want.

Faubourg Brewing Firm: A Give attention to Extra Than One Brewery

Faubourg Brewing Co. operates just a little in a different way. Whereas Yards and Brooklyn Brewery wanted tools to cowl simply their very own beers, Faubourg is seeking to develop not solely its personal manufacturers, however the beers of different breweries as effectively.

In September of 2022, Faubourg (previously Dixie Brewing) introduced a merger with three craft breweries—Oyster Metropolis Brewing, Catawba Brewing, and Palmetto Brewing. Because the co-packer, Faubourg now brews beers from every of those manufacturers out of its pretty new $30 million, 80,000-sq-ft facility in New Orleans.

“We’re aggressively constructing a brewery conglomerate like a small CANarchy and persevering with to search for extra companions in that area that may be mutually useful both by a distribution community or manufacturing area,” says Dan Griffin, Director of Brewing Operations that joined Faubourg in July of 2021.

To be able to transfer at this breakneck tempo whereas nonetheless offering the best high quality beers for not solely themselves, but in addition different manufacturers, Griffin says they wanted to spend money on tools within the new area that might be as much as the duty.

After wanting into a number of totally different tools suppliers, Faubourg went all out, selecting Alfa Laval to provide its chilly block space with an Alfa Laval ALDOX, Alfa Laval CARBOBLEND, Alfa Laval Brew 250 bottom-fed airtight sharpening centrifuge, and Alfa Laval Flexitherm.

With co-packing now an enormous a part of Faubourg’s enterprise, Griffin says, “The Flexitherm is a big purpose we’ve been in a position to do this efficiently…for our measurement, that’s a novel characteristic.” He says for a lot of the manufacturers of their portfolio—Catawba, Palmetto, and Oyster Metropolis—these particular person breweries would by no means have the capital and even area to spend money on a Flexitherm on their very own.

However as a result of they’re in a position to brew their beer out of Faubourg’s outfitted facility, they’ll have conversations with wholesalers and guarantee them of each the standard and shelf lifetime of their beer. “We’re forward of the sport and we’ve mitigated a variety of points,” says Griffin, who trusts the method a lot that he runs nearly all of their very own business merchandise by the Flexitherm, “which frankly permits me to sleep higher at night time and makes our QA supervisor’s life a hell of loads simpler.”

Plus, consistency in tools throughout the board has maximized Faubourg’s objectives to provide high-quality merchandise throughout all their manufacturers each time.

For instance, Faubourg additionally runs all the pieces by their Brew 250 centrifuge. “We’d be completely useless with out our centrifuge,” says Griffin.

General, as Faubourg units its sights on welcoming much more breweries into its portfolio, they’ve set themselves up for one of the best likelihood at success by investing in a brewhouse outfitted with essential items of apparatus from Alfa Laval.