It’s a story as outdated as time, or perhaps not fairly as outdated as time, however nonetheless outdated… your beer has completed fermenting, you excitedly switch it to a keg and wait patiently. Effectively, perhaps not so patiently. On daily basis or two you draw some beer to see the place it’s at… it tastes wonderful but it surely’s not carbonating. You assume you’re simply being impatient, however then the times proceed to pile up. You’re getting a bit carbonation, however not a lot. Is that this beer damaged? Or, have the essential rules of fluid dynamics simply failed?

First Issues First…

You’ve in all probability already completed this, however it is advisable to be certain your system is balanced and that each the temperature and strain ranges are set to accurately

See: Step by Step: Balancing Your Kegerator Draft System

Verify For Leaks

You’ve in all probability already completed this too, however it is advisable to be certain your kegerator is leak-free.

Why Your Beer Nonetheless Gained’t Carbonate…

In my expertise, continued carbonation issues are a dependable signal of… a CO2 leak. You could be satisfied that your CO2 strains are leak-free, however… it’s potential you’re lacking one thing. Even a really small leak will foil the carbonation course of.

Fuel goes to need to take the trail of least resistance. Leaking out of a foul o-ring, or different sluggish, small leak is less complicated than dissolving into resolution.

For those who’re studying this odds good you’ve checked for quick, giant leaks. If that’s the case, take an in depth have a look at the gasoline submit o-rings and gasoline dip tube o-rings.

In my view probably the most tough spot to test and the reason for many a misplaced CO2 tanks are… gasoline submit o-rings.

Testing at this level utilizing the “spray bottle methodology” (spray Star San in every single place and test for bubbles) is inconceivable or on the very least tough and messy. Leaks will solely floor right here when a gasoline QD is definitely engaged. The issue is, you may’t simply see that spot when a QD is on.

The issue acknowledged extra merely… You want a QD on to see if it’s leaking, however you may’t see it if a QD is on. You need to use what I name the strain gauge methodology to test for general leaks. However even utilizing that methodology you understand that you’ve got a leak but it surely provides no indication the place it’s at.

Be fast to switch gasoline aspect o-rings… I’m fast to switch gasoline submit (and gasoline dip tube) o-rings. Past sluggish and no-carbing beers, a foul gasoline aspect o-ring can result in empty tanks. That’s a waste of money and time and it’s irritating.

These o-rings value pennies every whenever you purchase them in bulk. Liberally changing these can save time, cash and frustration.

Associated:

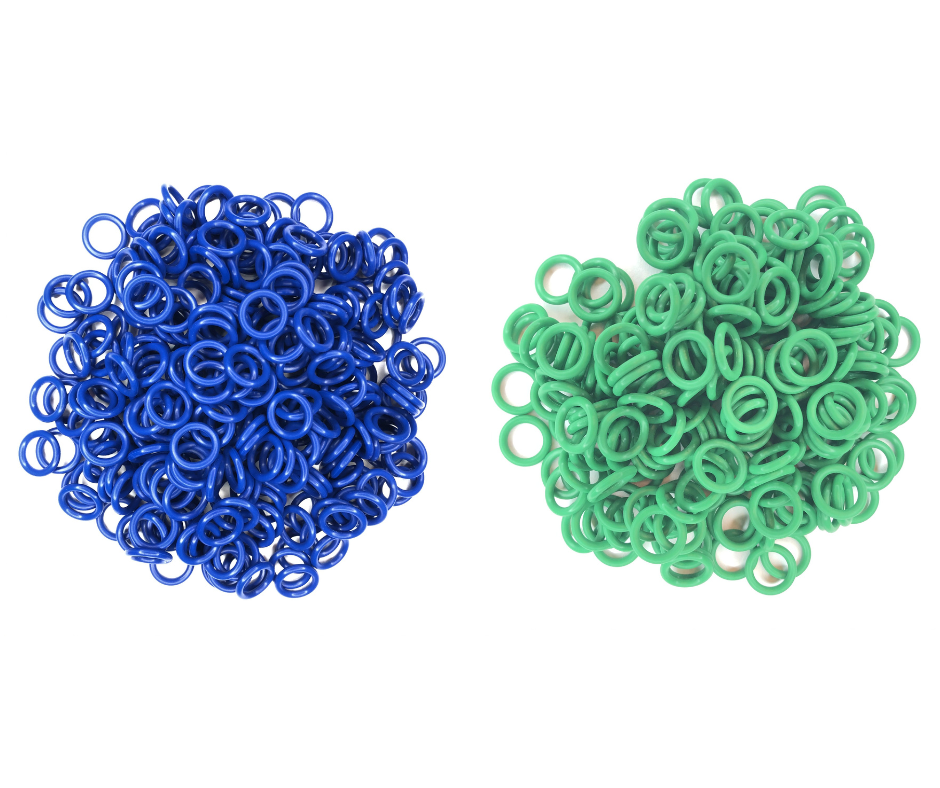

Shade Coded Put up O-Rings for Straightforward Identification:

Valuebrew carries two shade schemes to paint keg posts. Doing this lets you rapidly establish keg posts. Grey and Black match customary keg QD colours. Blue and Inexperienced are supposed to be remembered by “Blue for Beer” and “Inexperienced for Fuel”. All choices are constructed from FDA rated silicone. Since they work equally effectively on gasoline and liquid posts you too can combine and match to give you your personal shade coding customary.

Additionally: Kegerator Ideas & Gear | Keg Restore Half #s | Latest Keg Finds

Our High Draft Assets

Extra Homebrew Finds!

This can be a High Put up! See: All High Posts

Ensure that the parts you employ are suitable and rated to your supposed utility. Contact producer with questions on suitability or a particular utility. All the time learn and comply with producer instructions. toppost:carbproblems tag:tpr